Cardiovascular diseases (CVDs) remain the leading cause of global

mortality, accounting for 32% of total deaths annually according to the World

Health Organization. As the incidence of myocardial infarction, ischemic stroke,

and pulmonary embolism surges with aging populations and sedentary lifestyles,

the demand for effective thrombolytic agents like urokinase is escalating

sharply. The global urokinase market is projected to grow at a CAGR of 6.8% from

2025 to 2033, reaching USD 485.6 million by the end of the forecast period. In

this booming market, selecting a forward-thinking Urokinase Manufacturer that

embraces innovative and sustainable production technologies has become a

critical criterion for healthcare providers and pharmaceutical distributors

seeking reliable, high-quality supplies.

Traditional urokinase production, relying on urine extraction, faces

inherent challenges including limited raw material supply, batch-to-batch

variability, and potential safety risks. A pioneering Urokinase Manufacturer now

addresses these pain points through the integration of green biotechnology and

recombinant DNA technology. Unlike conventional methods that use toxic solvents

and generate excessive waste, green synthesis strategies such as biocatalysis

and eco-friendly fermentation significantly reduce environmental footprint while

enhancing production efficiency. For instance, the adoption of Escherichia coli

(E. coli) for recombinant urokinase expression—building on groundbreaking

research in protein renaturation technology—has revolutionized large-scale

production, achieving purity levels exceeding 99% and eliminating the risk of

viral transmission associated with urine-derived products.

The technical advancements of a leading Urokinase Manufacturer extend

beyond production to product optimization. Modern recombinant urokinase variants

offer superior pharmacokinetic profiles, including enhanced fibrinolytic

specificity and a reduced bleeding risk—addressing the narrow therapeutic window

that has long challenged thrombolytic therapy. Additionally, innovative

formulations such as single-bolus administration options simplify clinical

application, improving emergency treatment efficiency for acute CVD events.

These advancements align with the expanding scope of urokinase applications,

which now include arterial occlusions and catheter clearance alongside

traditional indications, further driving market demand for technologically

advanced products.

Global regulatory compliance and supply chain resilience are another

hallmark of a trusted Urokinase Manufacturer. With the thrombolytic drugs market

set to grow at an 8.1% CAGR to USD 6.4 billion by 2034, manufacturers must

adhere to stringent international standards such as USP, EU GMP, and WHO

guidelines to ensure product quality and accessibility. Leading manufacturers

achieve this through vertical integration—controlling every stage from

recombinant strain development to finished product distribution—and establishing

diversified global supply networks. This strategic layout mitigates geopolitical

and logistical risks, ensuring stable supply even amid global healthcare

disruptions.

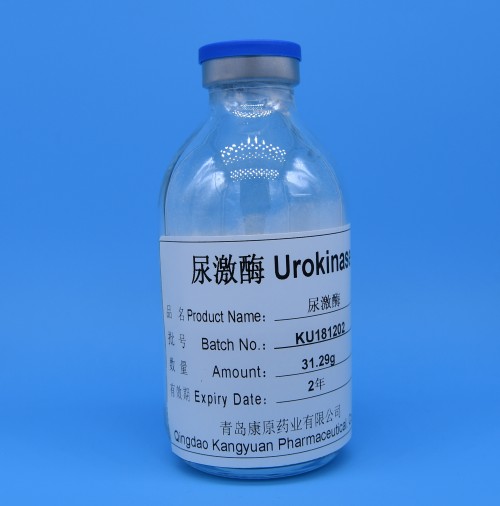

As a professional Urokinase Manufacturer, Kangyuan is at the forefront of

integrating green biotechnology and recombinant technology into thrombolytic

drug production. Our state-of-the-art manufacturing facilities leverage E.

coli-based recombinant expression and eco-friendly biocatalysis processes,

delivering high-purity urokinase products with consistent potency and enhanced

safety profiles. We strictly comply with global regulatory requirements,

ensuring our products meet the highest standards for clinical use worldwide.

Whether you are seeking reliable urokinase supplies, technical support for

formulation optimization, or collaborative research opportunities, our expert

team is dedicated to providing personalized solutions tailored to your needs.

Contact Kangyuan today to partner with a forward-thinking Urokinase Manufacturer

and access cutting-edge thrombolytic therapies that advance patient care.