The global burden of thromboembolic diseases, including acute ischemic

stroke, deep vein thrombosis, and pulmonary embolism, is escalating with the

aging population, driving a steady growth in the demand for effective

thrombolytic agents. Urokinase, a key drug that activates the fibrinolytic

system to dissolve blood clots and restore vascular patency, has become a

first-line therapy in clinical practice. As the market expands—projected to

reach $673 million by 2031 with a stable CAGR—selecting a reliable Urokinase

Manufacturer has become crucial for healthcare providers and pharmaceutical

distributors. A leading Urokinase Manufacturer distinguishes itself not only

through product quality and compliance but also through technological innovation

and global supply chain resilience, which are essential to addressing the

evolving clinical needs and market challenges.

Technological innovation is the core competitiveness of a top-tier

Urokinase Manufacturer, especially in the shift from traditional extraction

methods to advanced biotechnologies. Historically, urokinase was primarily

derived from human urine, which posed limitations in terms of yield, purity, and

supply stability. Today, leading manufacturers are adopting microbial

fermentation and recombinant DNA technologies to overcome these drawbacks. For

instance, microbial fermentation technology has significantly improved product

purity (reaching over 99%) and reduced production costs by 40%, while

recombinant urokinase ensures consistent potency and minimizes the risk of

contamination. These technological advancements not only enhance the safety and

efficacy of urokinase products but also support the development of innovative

formulations such as long-acting and targeted urokinase, which reduce dosing

frequency and bleeding risks, further improving patient compliance.

Additionally, the latest clinical research, such as the POST-UK study published

in JAMA, has confirmed the effectiveness of urokinase in improving functional

outcomes for acute ischemic stroke patients after endovascular reperfusion,

opening new avenues for product application and emphasizing the need for

high-quality manufacturing.

Global market layout and supply chain resilience are another critical

criterion for evaluating a Urokinase Manufacturer. The global urokinase market

is highly concentrated, with the top three manufacturers accounting for

approximately 50% of the market share. While European and American enterprises

dominate the high-end market with high-purity products, Chinese manufacturers

are gaining traction in emerging markets such as India and Southeast Asia

through technology transfer and localized production. Driven by the "Belt and

Road" initiative, Chinese medical assistance projects have further boosted

urokinase exports. A competitive Urokinase Manufacturer must establish a

diversified global supply chain to mitigate risks from geopolitical changes and

regional policy adjustments. This includes vertical integration of the

industrial chain—from raw material sourcing to finished product distribution—and

compliance with international regulatory standards such as USP and EU GMP. Such

layout ensures stable supply and consistent product quality across different

regions, meeting the urgent needs of healthcare systems for life-saving

thrombolytic drugs.

Policy support and cost-effectiveness also enhance the market

competitiveness of a Urokinase Manufacturer. As urokinase is included in the

medical insurance catalogs of many countries, patient out-of-pocket expenses are

reduced, further stimulating market demand. Leading manufacturers leverage

technological advantages to balance high quality and cost control, offering

biosimilar urokinase products that have the same efficacy and safety as

reference products but at a lower cost. This not only expands access to

urokinase in resource-constrained regions but also meets the cost-saving needs

of global healthcare systems. Additionally, active collaboration with clinical

research institutions to participate in trials such as POST-UK helps

manufacturers optimize product formulations and expand indication scope,

strengthening their leading position in the market. Ongoing research into the

potential of urokinase in tumor infiltration and metastasis also provides

long-term growth drivers for forward-thinking manufacturers.

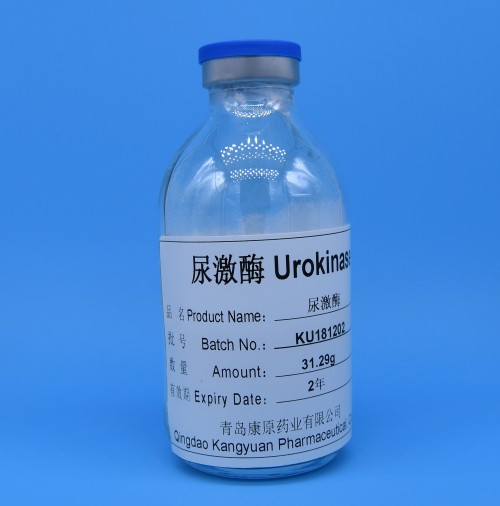

As a professional Urokinase Manufacturer, Kangyuan is committed to leading

the industry through technological innovation and global collaboration. We adopt

advanced microbial fermentation and recombinant DNA technologies to produce

high-purity urokinase products that meet global regulatory standards, ensuring

consistent potency and safety. Our diversified global supply chain and localized

production strategies guarantee stable product supply to markets across Asia,

Europe, and Southeast Asia. We actively participate in clinical research

projects to continuously expand the clinical application of urokinase and

provide tailored solutions for healthcare providers. Whether you are seeking

reliable urokinase supplies, technical support, or market expansion

collaboration, our professional team is dedicated to delivering high-quality

services and personalized support. Contact Kangyuan today to establish a trusted

partnership for advancing thrombolytic therapy and meeting global healthcare

needs.