Urokinase is a specific enzyme involved in the fibrinolytic

system, playing a crucial role in preventing blood clot formation. As a

therapeutic agent, urokinase finds applications in the treatment of various

medical conditions, including acute myocardial infarction, deep vein thrombosis,

and pulmonary embolism. In this article, we will explore the significance of

hormone API manufacturers in the production of urokinase and their contributions

to the biopharmaceutical industry.

Urokinase and Its Medical Applications: Urokinase, also known as

urokinase-type plasminogen activator (uPA), is a naturally occurring protein

present in humans. This enzyme acts on plasminogen, converting it into plasmin,

a proteolytic enzyme responsible for the breakdown of blood clots. By promoting

fibrinolysis, urokinase helps to dissolve blood clots, facilitating the

restoration of blood flow and preventing potentially life-threatening

complications.

Role of Hormone API Manufacturers: Hormone API manufacturers play a crucial

role in the production of urokinase for therapeutic purposes. They are

responsible for the extraction, purification, and formulation of this enzyme,

ensuring its efficacy, safety, and compliance with regulatory standards. The

following are key aspects of their involvement:

Extraction and Purification: Urokinase is primarily obtained through

recombinant DNA technology or from natural sources, such as human urine or

cultured cells. Hormone API manufacturers employ advanced biotechnological

methods to extract and isolate urokinase, ensuring high purity and eliminating

impurities that may compromise its therapeutic effect.

Protein Engineering and Optimization: Optimizing urokinase's properties and

functionality is crucial for its therapeutic application. Hormone API

manufacturers utilize protein engineering techniques to enhance urokinase's

stability, activity, and specificity against targeted clot lysis. This process

involves extensive research and development, aiming to improve therapeutic

outcomes and reduce potential side effects.

Quality Control and Regulatory Compliance: The production of urokinase by

hormone API manufacturers involves strict quality control measures to ensure its

safety, efficacy, and consistent performance. Adhering to Good Manufacturing

Practices (GMP) and regulatory guidelines, these manufacturers conduct

comprehensive analytical testing, stability studies, and process validations to

guarantee the highest standards of quality in the final product.

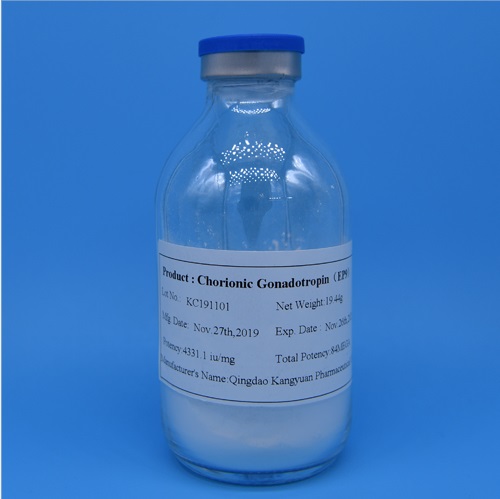

Large-Scale Production and Distribution: Hormone API manufacturers are

equipped to scale up the production of urokinase to meet global demand. They

ensure large-scale manufacturing processes that maintain consistent quality

throughout the production cycle. Their capabilities extend to packaging,

labeling, and safe distribution of urokinase to medical facilities

worldwide.

Hormone API manufacturers play a pivotal role in the

biopharmaceutical industry as they drive the production of urokinase for

therapeutic application. By employing advanced biotechnological methods and

adhering to rigorous quality control standards, these manufacturers contribute

to the availability of safe and effective urokinase products. Through their

expertise and dedication, hormone API manufacturers actively support medical

advancements, ensuring the treatment of life-threatening conditions, and

improving patients' lives around the world.