Ulinastatin, also known as urinary trypsin inhibitor (UTI),

is a glycoprotein that has gained significant attention in the medical field due

to its therapeutic potential. Ulinastatin is primarily used in the treatment of

acute pancreatitis, sepsis, and various inflammatory conditions. In this

article, we will provide an overview of the manufacturing processes involved in

ulinastatin production and highlight the crucial quality control measures

implemented throughout the production cycle.

Sourcing and Selection of Raw Materials: The first step in ulinastatin

manufacture is the sourcing and selection of high-quality raw materials. The

primary raw material required is porcine pancreatic tissue, which is rich in

trypsin inhibitor. Stringent guidelines are followed to ensure that the porcine

sources are healthy and free from any diseases or contaminants.

Extraction and Purification: The extraction process involves homogenization

of the porcine pancreatic tissue and subsequent solubilization to obtain the

crude extract. Various techniques, such as acid extraction or enzymatic

hydrolysis, are employed to extract ulinastatin. The crude extract undergoes

multiple purification steps, including filtration, centrifugation, and

chromatography, to remove impurities and obtain a highly purified ulinastatin

solution.

Formulation and Sterilization: After purification, the ulinastatin solution

is subjected to formulation processes, where appropriate excipients and

stabilizers are added to enhance stability and shelf life. The formulation is

prepared under strict aseptic conditions to prevent contamination. Terminal

sterilization, such as sterile filtration or heat treatment, is applied to

ensure the product's sterility.

Quality Control: Quality control plays a vital role in ulinastatin

manufacture to ensure the safety, efficacy, and consistency of the final

product. Quality control tests are conducted at various stages, including raw

materials, in-process samples, and the final formulated product. These tests

involve assessing the purity, potency, identity, and microbiological attributes

of ulinastatin. High-performance liquid chromatography (HPLC), enzyme-linked

immunosorbent assay (ELISA), and microbiological testing are commonly employed

methods.

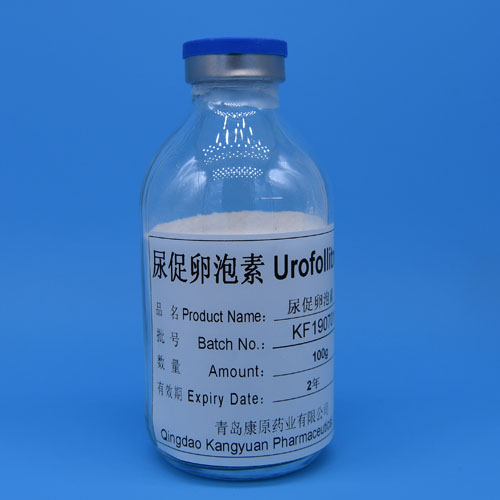

Packaging and Labeling: Once the ulinastatin formulation passes all quality

control tests, it is ready for packaging. The product is filled into sterile

vials or ampoules, which are then sealed to maintain the integrity and sterility

of the drug. Accurate labeling is essential to provide clear instructions for

use, dosage, storage conditions, and batch information.

The manufacture of ulinastatin involves a series of

well-defined processes, starting from sourcing high-quality raw materials to the

formulation, sterilization, and packaging of the final product. Strict adherence

to quality control measures throughout the production cycle ensures the safety,

efficacy, and reliability of ulinastatin. Continued advancements in

manufacturing techniques and quality control systems contribute to the

availability of high-quality ulinastatin for therapeutic use, benefiting

patients suffering from acute pancreatitis, sepsis, and inflammatory

disorders.