In the field of pharmaceuticals, the manufacture of Ulinastatin and the

usage instructions for Urofollitropin play vital roles. This article provides an

overview of these two important components in the medical industry.

Ulinastatin Manufacture: Ulinastatin, also known as urinary trypsin

inhibitor (UTI), is a protease inhibitor widely used in the treatment of various

inflammatory conditions. The manufacturing process of Ulinastatin involves

several key steps:

a. Sourcing of Raw Materials: The first step is to procure high-quality raw

materials required for the production of Ulinastatin. This includes sourcing

enzymes, buffer solutions, and other necessary substances.

b. Fermentation: The production of Ulinastatin involves fermentation, where

specific strains of microorganisms are cultivated in a controlled environment.

These microorganisms produce the required enzymes through fermentation.

c. Purification: Once fermentation is complete, the Ulinastatin is

separated and purified from the fermentation broth using various techniques such

as filtration, chromatography, and centrifugation. This ensures the removal of

impurities and the isolation of pure Ulinastatin.

d. Formulation and Packaging: After purification, the Ulinastatin is

formulated into the desired dosage forms, such as lyophilized powder or

injectable solutions. The final product is then packaged and labeled for

distribution.

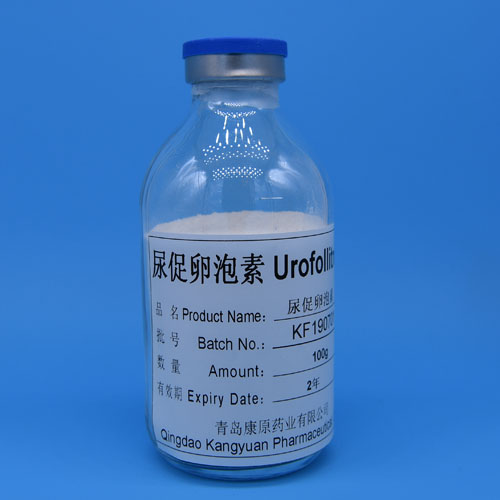

Urofollitropin Instructions: Urofollitropin, a follicle-stimulating hormone

(FSH), is used in fertility treatments to stimulate the development of multiple

follicles in the ovaries. Proper administration and adherence to the

instructions are crucial for the effective and safe use of Urofollitropin. Here

are some key instructions for using Urofollitropin:

a. Dosage and Administration: Urofollitropin is typically administered by

subcutaneous injection. The dosage and injection frequency are determined by the

prescribing healthcare professional based on individual patient needs. It is

important to follow the prescribed dosage and injection technique

accurately.

b. Storage and Handling: Urofollitropin should be stored in a cool and dry

place, away from direct sunlight and moisture. Proper handling procedures should

be followed to maintain the integrity and efficacy of the medication.

c. Monitoring and Consultation: During the treatment with Urofollitropin,

regular monitoring is essential. This may include blood tests, ultrasound scans,

and hormone level assessments. Patients should closely follow up with their

healthcare provider and report any concerns or side effects experienced during

the treatment.

Conclusion: Ulinastatin manufacture and Urofollitropin instructions are

crucial aspects of the pharmaceutical industry. The careful manufacturing

process of Ulinastatin ensures the production of a high-quality and effective

protease inhibitor. On the other hand, adhering to the instructions for

Urofollitropin usage is vital for its safe and successful use in fertility

treatments. Understanding the manufacturing process and following the

instructions accurately contribute to the overall effectiveness and positive

outcomes of these pharmaceutical components.