Human Menopausal Gonadotropin (hMG) is a hormone medication used in

fertility treatments to stimulate ovulation. The manufacturing process of hMG

involves a series of delicate steps to ensure the purity, potency, and quality

of the final product.

The first step in the manufacturing process is the collection of urine from

postmenopausal women, which is rich in the hormones LH (Luteinizing Hormone),

FSH (Follicle-Stimulating Hormone), and hCG (Human Chorionic Gonadotropin). The

urine is then screened for potential contaminants such as bacteria or

viruses.

Next, the urine undergoes a series of processes to extract and purify the

hMG hormone. This includes filtration, adsorption, and ion exchange

chromatography techniques. These techniques ensure that the hMG is extracted in

its purest form, free from impurities.

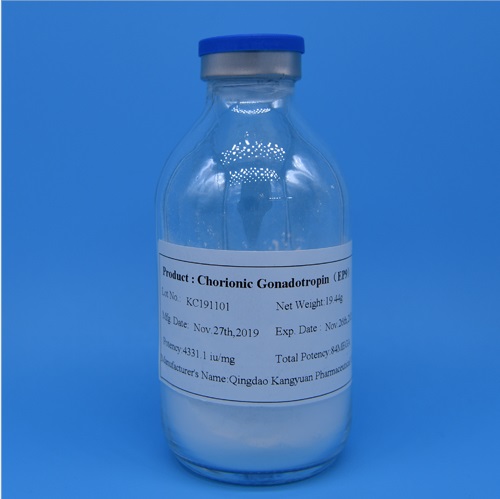

The purified hMG is then formulated into a sterile powder or liquid

injection. The formulation process involves adding sterile ingredients such as

stabilizers and preservatives to maintain the potency and stability of the final

product.

Quality control is an essential aspect of the manufacturing process of hMG.

The final product undergoes rigorous testing and analysis to ensure its safety,

potency, and purity. This includes testing for impurities, potency, and

sterility.

In conclusion, the manufacturing process of Human Menopausal Gonadotropin

is a highly specialized and delicate process that requires strict quality

control measures. The purity, potency, and quality of the final product are

essential to ensure its effectiveness in fertility treatments.