Ulinastatin is a protein drug that is derived from human urine or other

animal sources, such as pigs or cows. It is a type of protease inhibitor that is

used for the treatment of inflammatory conditions and shock.

The manufacture of ulinastatin involves several steps, including protein

purification and formulation. The following is a brief overview of the

manufacturing process:

Collection of raw materials: The starting material for ulinastatin

manufacture is collected from either human urine or animal sources.

Purification: The raw material is purified using various methods such as

fractionation, chromatography, and ultrafiltration to obtain the desired

protein.

Formulation: The purified protein is then formulated with excipients and

stabilizers to create a stable drug product.

Quality control: The drug product is subjected to rigorous quality control

testing to ensure its purity, potency, and safety.

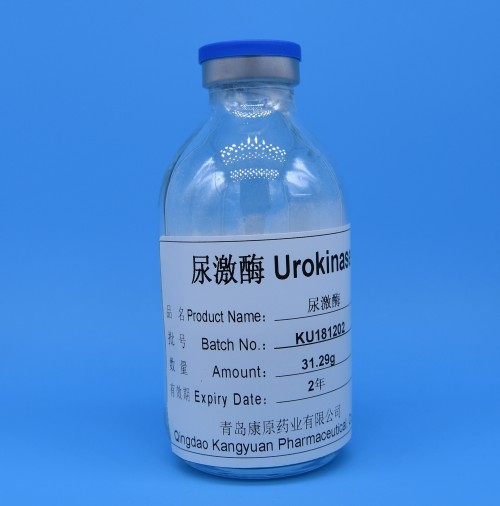

Packaging: The drug product is then packaged in sterile vials or cartridges

for distribution to hospitals and clinics.

Ulinastatin has been widely used in Japan and China for the treatment of

various conditions, such as acute pancreatitis, sepsis, and trauma. It has also

shown potential in the treatment of COVID-19 patients with severe respiratory

distress syndrome.

In conclusion, ulinastatin manufacture is a complex process that involves

several steps of protein purification and formulation. The resulting drug

product is subject to rigorous quality control testing to ensure its safety and

efficacy. The use of ulinastatin has shown promise in the treatment of various

inflammatory conditions and continues to be an area of active research.