Ulinastatin is a naturally occurring protease inhibitor that has been used

to treat various medical conditions, such as acute pancreatitis, sepsis, and

acute respiratory distress syndrome. Here is an overview of the manufacturing

process of ulinastatin:

Fermentation

The first step in the manufacture of ulinastatin is the fermentation of a

selected strain of bacteria, usually Bacillus subtilis or Escherichia coli. The

bacteria are cultured in a nutrient-rich medium under controlled conditions,

including temperature, pH, and aeration. The fermentation process can last from

several hours to several days depending on the specific strain of bacteria

used.

Harvesting

Once the bacteria have grown, they are harvested and separated from the

fermentation broth using centrifugation or filtration. The resulting cell pellet

is then washed with buffer solution to remove any extraneous proteins and other

unwanted materials.

Extraction

The cell pellet is then subject to several rounds of extraction, usually

with alkaline solution, to release the ulinastatin protein. The extracted

protein is then purified using techniques such as column chromatography,

ultrafiltration, and diafiltration to remove impurities.

Formulation

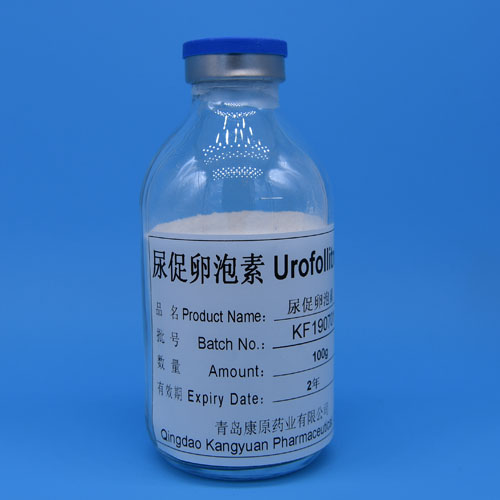

After purification, the ulinastatin protein is formulated into its final

dosage form, usually as a lyophilized powder or solution. Excipients such as

mannitol, lactose, or glycine may be added to stabilize the protein and improve

its solubility.

Quality control

Throughout the manufacturing process, strict quality control measures are

implemented to ensure the final product meets the required specifications for

potency, purity, and safety. Quality control tests may include assays for

protein concentration, purity, and activity, as well as tests for sterility,

endotoxins, and other impurities.

In conclusion, the manufacture of ulinastatin involves several complex

steps, including fermentation, harvesting, extraction, formulation, and quality

control. The final product must meet strict regulatory requirements before it is

considered safe and effective for use in patients.