Quality control and laboratory testing: Ulinastatin production requires

strict quality control and laboratory testing to ensure quality and reliability.

Choosing a manufacturer with GMP and ISO certification can ensure the quality

and reliability of the product.

Ingredients and purity: Ulinastatin ingredients need to be guaranteed in

purity and quality. During production, it is necessary to strictly control the

content and quality of impurities to ensure the therapeutic effect and safety of

the product.

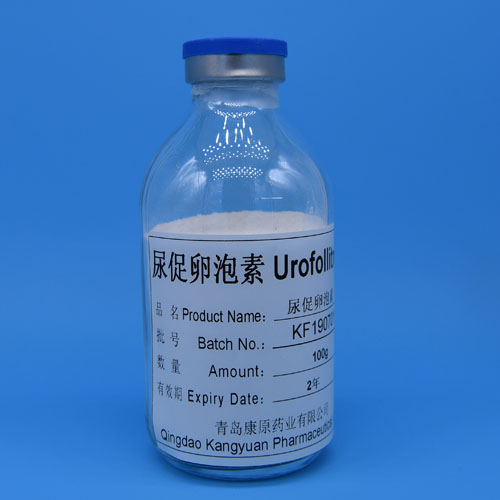

Shelf life and stability: Ulinastatin is a biological drug, and its

stability and shelf life need to be guaranteed. Choosing a manufacturer with a

long shelf life and stability can ensure the stability and effectiveness of the

product during use.

Quality testing and testing: During production, strict quality testing and

testing need to be conducted to ensure the quality and reliability of the

product. Choosing a manufacturer with higher testing and testing standards can

ensure the quality and safety of the product.

Packaging and transportation: The packaging and transportation of

Ulinastatin need to ensure the safety and integrity of the product. Choosing a

manufacturer with high-quality packaging and transportation standards can ensure

the safety and integrity of the product during transportation and storage.

In summary, choosing a manufacturer of Ulinastatin requires attention to

several key factors, including quality control and laboratory testing,

ingredients and purity, shelf life and stability, quality testing and testing,

as well as packaging and transportation. This can ensure the quality and safety

of the product.