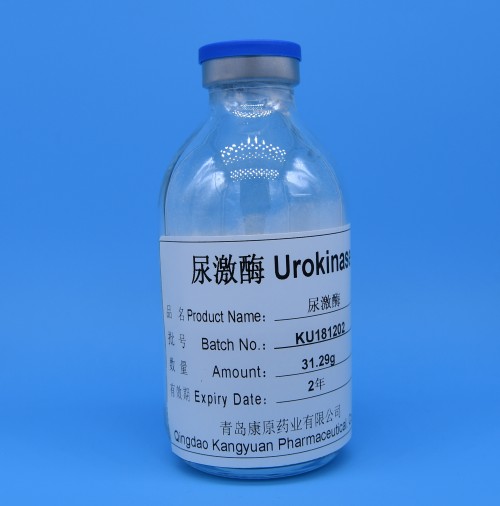

Urokinase supplier specializes in the design, production and supply of

high-quality biological processing and purification equipment, such as urokinase

extraction equipment, gonadotropin production equipment, etc. Kangyuan is a

professional manufacturer of urokinase. The following is to explain the analysis

of the basic refining process of urokinase products, the following specific

learning.

1.Collection: After the bucket is filled with urine, store it in a cool

place. Adjust urine PH to below 6.5. In order to prevent the deterioration of

urine in summer, 0.8 phenol was added.

2, precipitation treatment: urine to keep below 10℃, with sodium hydroxide

PH value to 8.5, mix evenly, stand for 1 hour, after precipitation with a rubber

pipe siphon out the supernatant, acidification to PH value 5-5.5.

3, diatomite adsorption. According to the proportion of acidified urine

volume L, pre-cleaned and processed into neutral diatomite, which was adsorbed

at 5℃ for hours.

4. Elution. First, the diatomite adsorbent was washed once with 5℃ cold

water, and then loaded into the diatomite column, washed with 0.02% ammonia, so

that the washing solution changed from muddy to clear, and then washed with 0.02

ammonia and 0.1m sodium chloride solution immediately. When the water flowing

from the diatomite column becomes clear and muddy, it begins to collect

urokinase.

The above is kangyuan xiaobian for you to sort out and share the product

refining process, I hope to help you understand the product; Later continue to

sort out and share for you, welcome to continue to pay attention to us.