Urokinase production equipment is the main production or from the

application of urokinase products equipment, there are many different kinds of

this type of equipment and is equipped with a separate device inside the

equipment, the separation device is called "chromatography column",

chromatography column is made of organic glass, simpler to use smart, and easy

to operate, the transparency of organic glass is wonderful, In this way, the

color change of the material inside can be clearly observed when operating the

equipment, which improves the separation efficiency. Let's take a look at how

the device works.

1. There are many processes for the production of urokinase, and the most

frequently used methods are algal soil method and 724 resin method.

2. The main operation procedure is to collect the urine first, using a

special plastic bucket for collection.

3. Collect fresh urine.

4. Only male urine can be collected. Female urine can contain red blood

cells and other components, and if female urine is used, protease in urine will

be degraded.

5. Urine is best kept below 10 degrees Celsius and needs to be treated as

soon as possible. Rapid cooling can be done with ice or other methods such as

refrigeration.

6. Regulate your urine PH.

7. Let the urine sit for an hour and siphon the supernatant. Any grayish

sediment needs to be removed.

8. Adsorption urokinase: The clear liquid on the siphon is prepared for

stirring and adsorption, and the time is 1 hour. The resin will naturally sink,

remove the residual urine and collect the resin.

9. Wash the collected resin three times with tap water, and then wash it

three times with non-ionized water until the urine is colorless.

10. Pour the urine into the equipment for elution. Do it in two batches for

30 minutes each.

11. Add solid ammonium sulphate to the eluted liquid, and add hydrochloric

acid when a certain saturation is reached, and precipitate for 6 to 7 hours.

12. The collected brown urokinase precipitates were filtered with pulp,

drained and stored in a cryogenic freezer or refrigerator freezer.

13. Finally, the resin regeneration, the new resin soaked in alcohol for

three hours, washed with water, and then soaked in distilled water for 24 hours,

the use of chemicals soaked in water can be used.

This is the working principle of the urokinase production equipment.

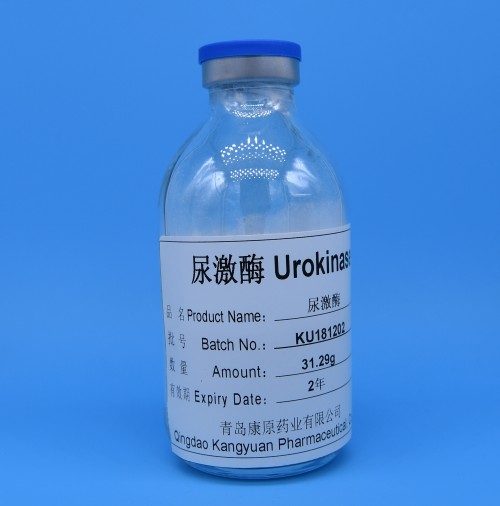

Welcome to contact Kangyuan company if necessary