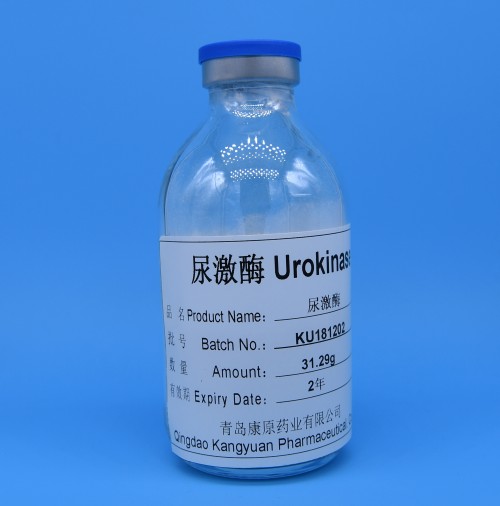

We all know that urokinase is a major drug for the treatment of diseases

like thrombosis, but do you know how urokinase came from? We need to use today's

leading urokinase extraction equipment, which has gone through four generations

of products. The integrated processing equipment is put into use, and the

extraction of products is faster and the quality of products is very good.

Today, I want to share with you the extraction principle of the equipment.

1.Samples should be collected and stored in a cool place after the bucket

is filled with urine, and the PH value of urine should be adjusted to below 6.5.

In summer, urine is easy to deteriorate.

2. For precipitation treatment, urine should be kept below 10 degrees

Celsius, with sodium hydroxide to adjust the PH value to 8.5, stirring evenly

and then standing for one hour. After precipitation, the supernatant should be

siphon out with a rubber tube and acidified to a PH value of 5 to 5.5.

3. Diatom adsorption treatment: According to the volume of acidified urine,

add the pre-cleaned diatomite and treat it into neutral diatomite, which needs

to be adsorbed at a temperature below 5 degrees Celsius for one hour.

4. The elution steps is with five degrees of diatomite the adsorbate on the

first cold water washing time, and then load the diatomaceous earth column, with

0.02% of the ammonia washing, make clear eluate by turbidity, ammonia with 0.02

and 0.1 m nacl solution washing, when the diatomaceous earth column into the

water from the pay, you can begin to collect the urokinase.

5. Generally 15 litres of crude urokinase fluid can be collected from 1000

kg of urine.

The principle of extraction of urokinase extraction equipment is introduced

to you here, if there is a need to contact us directly.