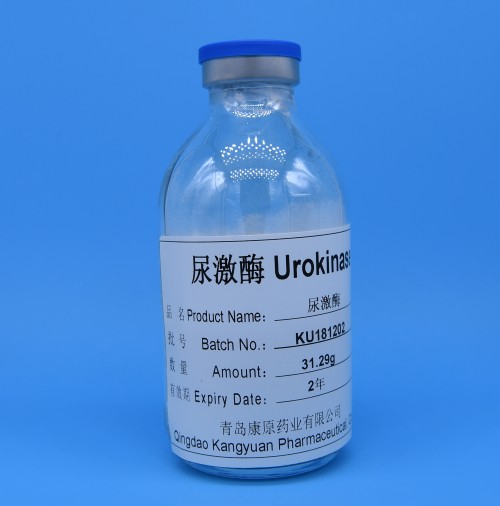

Urokinase production equipment about the correct operation process of

mixing tank equipment, we through the literal understanding is only used for

mixing a device, in fact, otherwise the equipment can also be mixed, blending,

homogenization and other operations, now there is stainless steel equipment, its

design structure and configuration more standardized and humanized, Next, we

will introduce the correct operation process of the equipment.

The correct operation process of the stirring tank equipment summarized by

the urinase manufacturer for you is as follows:

1. Operators are required to clean in accordance with procedures and

hygiene.

2. Operators must repair and maintain the equipment in accordance with the

procedures.

3. Check whether the equipment is in normal condition and confirm that the

equipment has been cleaned and meets the requirements.

4. Check whether the connection between the stirring slurry and the motor

is firm and reliable.

5. Choose the mixing tank according to the amount of the material liquid to

be processed. Generally, the sample amount of the material liquid is not less

than one third of the volume of the mixing tank.

6. At this time, it is necessary to slowly adjust the speed regulating

knob, also known as the frequency conversion speed regulator, so that the mixing

speed is slowly increased, until the required speed can be.

7. Select the speed regulating knob to the position where the speed is

zero, add the material liquid and turn on the power switch.

8. After the equipment is used, turn off the power.

9. Cleaning and disinfection shall be carried out in accordance with the

Standard Operating Procedures for Cleaning and Disinfection of Stirring

Tanks.

Urokinase manufacturers will explain the operation process of mixing tank

equipment for you to here, if there is a need to contact us directly, welcome to

inquire!