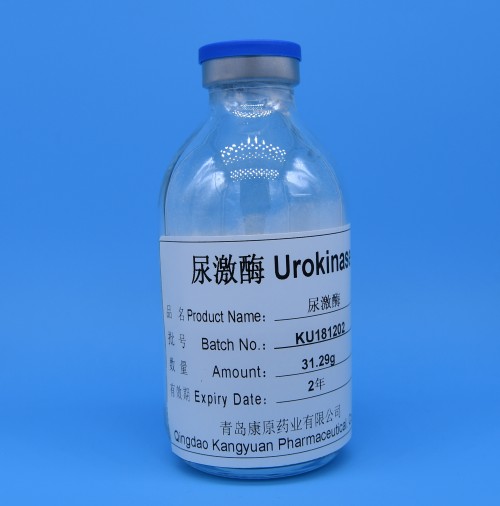

In the process of production and is made with urokinase indispensable a

device that is the drum, then mixing tank just as its name implies is used for

mixing equipment, in addition to stir the device the mixed, harmonic, the effect

of homogeneous product, the equipment in the whole mixing process can realize

the front-rear automatic control, automatic mixing control or other manual

control can be implemented, So let's take a look at that.

The maintenance methods of stirring tank equipment introduced by the

urokinase manufacturer are as follows:

1. The mixing tank equipment is atmospheric pressure equipment. If the

pipeline of the heat exchanger is smooth, it is also regarded as atmospheric

pressure.

2. The reducer needs to be equipped with industrial gear oil, the first run

for 20 days (after the oil and clean the oil in the tank, after every 3-5 months

to replace and clean the tank.

3. If the equipment is equipped with a condenser, it can be judged whether

the heat exchange pipe should be cleaned according to the heat exchange

effect.

4. The loading amount in the mixing tank should be strictly in accordance

with the effective volume of the mixing tank. Overloading is strictly prohibited

to avoid burning out the motor or damaging the reducer and other components.

5. If the equipment is not used for a long time, it should be cleaned,

lubricated everywhere and cut off the power supply.

Urokinase manufacturers will first introduce you here, more information

please continue to pay attention to us.